Fluidized Bed for Biochemical Waste Water Treatment

Objective

Fluidized-bed reactors work by allowing fluid to flow upward through a bed of particles and allowing the particles to react with the fluid (particularly under turbulent flow, which increases contact) in order to purify it.

The project objective was to design a fluidized bed column for biochemical wastewater treatment based on the concepts of hydrodynamics. The target bed expansion that the designed column needed to reach was 28%.

Skills: Experimental Design, Research, Fluid Theory

Spring 2022 - Summer 2022

Design Process - Experimental Data Collection

To begin the column design, various research papers were analyzed to determine an effective procedure that would allow us to validate the correlations from these papers. The main correlations that needed to be validated were the Ergun and Richardson-Zaki equations.

Using flowrate and pressure measurements over 3 different columns in the experimental setup, enough data was collected to compare experimental values against those from the correlations.

Experimental packed bed apparatus

Design Process - Validating Important Correlations

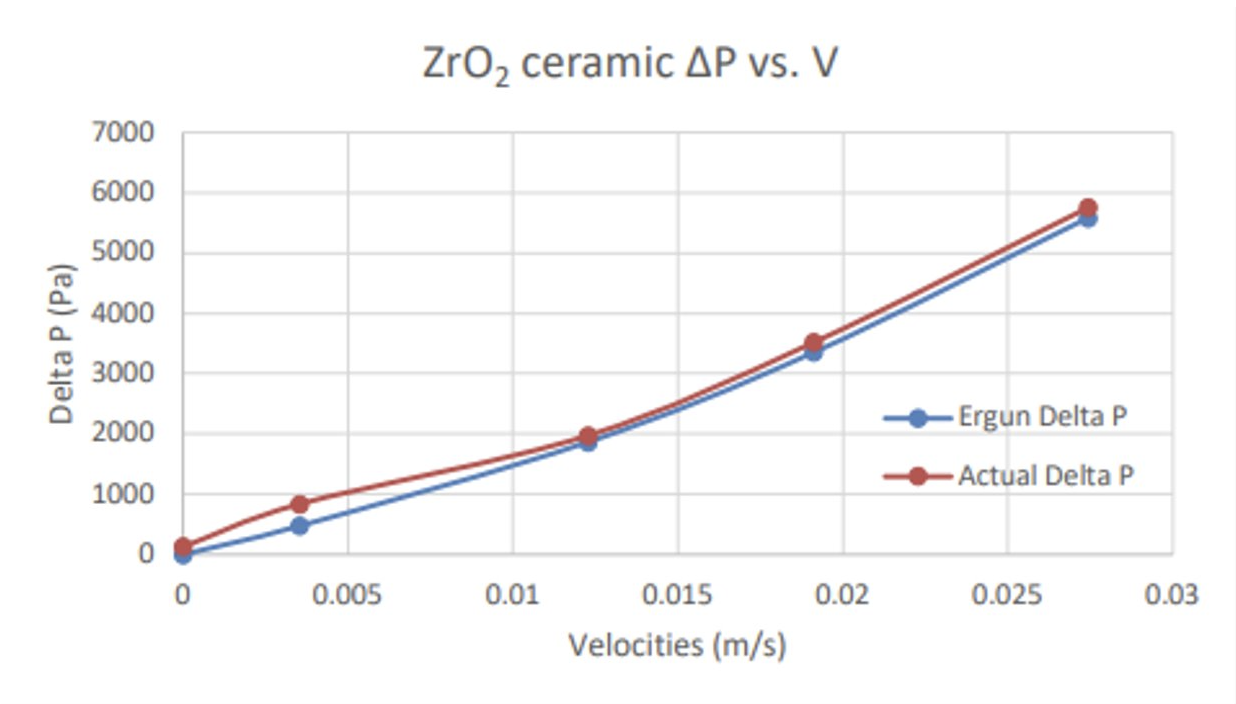

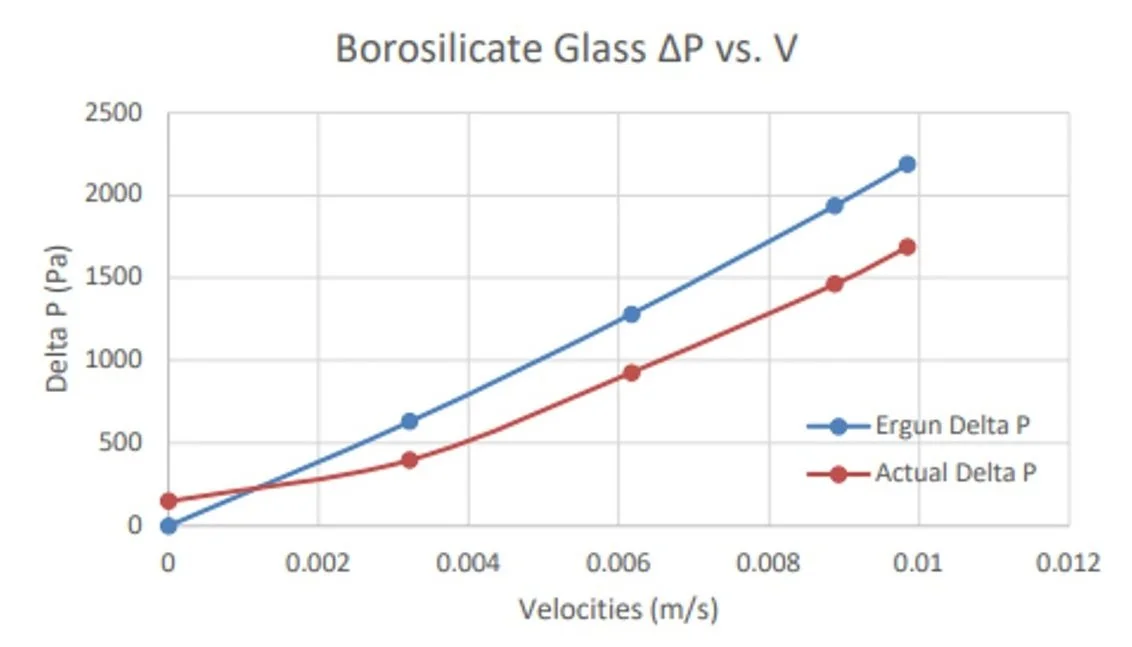

To validate the Ergun equation, fluidization velocity values were calculated from the flowmeter readings, and then converted into differential pressure values, using the correlation. These experimental and theoretical figures were then compared graphically (as shown below).

For validation of the Richarson-Zaki equation, the equations for Reynold’s number, drag coefficient, and terminal velocity were iterated over until constant values of terminal velocity were found. These were then used in the Richardson-Zaki equation to find superficial velocity. Once these values were linearized and compared to the experimental figures, it was evident that the correlation was validated.

Design Process - Column Design

To determine the optimum column diameter, a 28% bed expansion (which was a proven value from literature), was first used to determine porosity. The Richarson-Zaki equation was then used to determine the superficial velocity, which would give the optimal diameter at the experimental flow rate. This process is described in the steps below. Once the diameter was found, the Ergun equation was then used to determine hydrodynamic properties and bed specifications.

Steps for determining the optimal column diameter

Results and Reflection

After all the correlations were validated, the column diameter was determined to be 1.06 m, while the terminal and superficial velocities were 0.0889 m/s and 0.0153 m/s respectively. These would provide an effective 28% bed expansion for the extraction of phenolic acid out of the wastewater.

What made this project so challenging, and therefore so rewarding, was that just 3 research papers were our starting point. Searching through a variety of correlations and understanding a complex new topic, to completely design an experiment proved to be incredibly challenging. The most valuable thing I learned from this project was to break down a complex end goal into smaller, more digestible parts. By starting with just the Ergun and Richardson-Zaki equations, which are universally applicable for fluidized beds, the other pieces fell into place much more easily. It was interesting to see applications from previous courses such as fluid dynamics and force balances, all contribute towards the complex bed design.